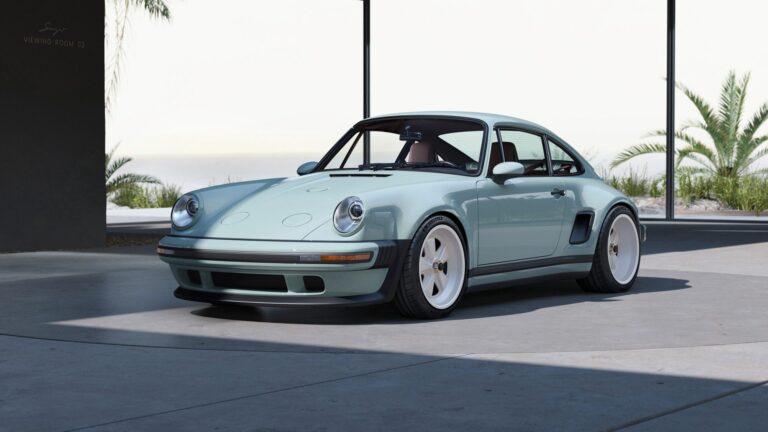

Singer, a California-based luxury specialist that restores and reimagines classic Porsche 911s in collaboration with their owners, has reimagined the Porsche 911 Carrera Coupe, incorporating a 420bph, naturally aspirated flat six.

Inspired by the rare wide-body variant of the 911 Carrera from the 1980s, the Porsche 911 Carrera Coupe Reimagined by Singer has been restored around the original Type 964 monocoque, with chassis strengthening developed in consultation with Red Bull Advanced Technologies, and features reimagined carbon fiber bodywork for aesthetic and functional performance. The reborn flat six has been based on the Type 964’s engine, with 4.0L capacity, four valves per cylinder, variable valve timing, water-cooled cylinder heads and air-cooled cylinders.

Rob Dickinson, Singer’s founder, executive chairman and creative director, said, “In the 1980s, you could order a new 911 Carrera with the pumped-up bodywork of the Turbo but powered by the company’s latest, naturally aspirated flat six. It became known as the Carrera with Super Sport Equipment. Our services reference this car and celebrate the era with a vision for an ultimate, naturally aspirated, G model 911, reimagined for the 21st century. At its heart is a remarkable flat six, bringing together our learnings from the last 15 years and adding variable valve timing for the first time.”

Restoration of the chassis

The first step of the restoration involved the owner’s car being carefully disassembled. The interior was removed, as was the exterior bodywork and all mechanical components, until the steel monocoque (chassis) was revealed. The chassis was assessed, cleaned and prepared so that it was in optimal condition for the next stages of restoration. During this phase, chassis strengthening, developed in consultation with Red Bull Advanced Technologies, was applied to enhance the rigidity of the original Type 964 monocoque. Red Bull used simulation and structural analysis, which led to the development of a chassis strengthening system using composite and steel reinforcement.

Engine and transmission

The engine draws on learnings from the DLS program, where Singer’s first four-valve cylinder head was born, with Singer continuing to explore the performance potential of the Type 964’s flat six through a continuous process of careful optimization and the development of a revised four-valve cylinder head.

Singer jointly developed this engine with Cosworth, which assisted with the variable valve timing, combustion chamber design and intake and exhaust path. The naturally aspirated engine uses water-cooled cylinder heads combined with air-cooled cylinders. Together, these features help the 4.0L flat six to develop 420bhp and broaden the torque delivery across a wider range of engine speeds.

Singer says that the engine will rev to over 8,000rpm, and that the car can feature an optimized, six-speed manual gearbox, sending power to the rear wheels, to “encourage drivers to explore that range”. A raised gear shifter may be specified with an exposed shift mechanism.

A new titanium exhaust system also provides free breathing for the flat-six.

Ground control

Four-way adjustable dampers with electronic damping control can be adjusted from the driver’s seat and incorporate a nose lift system. Carbon ceramic brakes may be specified, sitting behind 18in center-lock wheels, providing deep reserves of stopping power. The driver may select from five drive modes (road, sport, track, off and weather) to adjust the levels of intervention from the traction control and electronic stability control. The car is fitted with the latest Michelin pilot sport tires.