Red Bull Advanced Technologies has joined forces with Singer to design a strategy for increasing the torsional stiffness of Type 964 Cabriolets and Targas reimagined through Singer’s Classic Turbo services.

Singer’s process begins when a 964-generation Porsche 911 Cabriolet or Targa is provided for personalised restoration. The vehicle will be fully disassembled to expose the steel monocoque, which will then be assessed, cleaned and prepared for the subsequent stages of restoration.

Through the collaboration, Red Bull Advanced Technologies has provided its expertise in simulation and structural analysis. The Porsche 964 chassis has been digitally modeled using scanned data and manual measurements, with finite element analysis (FEA) software used to calculate the torsional stiffness of the different variants of the car (with and without a roof). The FEA model was then refined until the predicted stiffness values matched those recorded in physical tests.

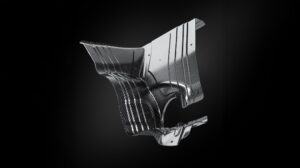

Having correlated the model, Red Bull Advanced Technologies used it to assess which parts of the open-roof structure were working the hardest to resist the applied torsion, primarily through looking at the strain energy. Using this, a formation of 13 carbon fiber structures were then designed to reinforce these parts, while still respecting the need to preserve the original Type 964 chassis and accommodate packaging requirements. The reinforcing structures were then built into the correlated FEA model, and tuned to give the required torsional stiffness level. A prototype vehicle featuring the reinforcing structures was then tested as a final validation of the analysis work.

The 13 carbon fiber reinforcing structures developed by Red Bull Advanced Technologies are bonded to the 964 monocoque during the restoration process, increasing torsional rigidity by 175%. This increased chassis rigidity benefits handling, braking and overall refinement, with the driving experience of the open-roofed cars now matching that of the coupe.

Rob Gray, technical director of Red Bull Advanced Technologies, said, “Our expertise is derived from relentless competition and success at the very highest levels of motorsport. We apply that expertise to engineering challenges across a wide variety of projects and industries. The challenge from Singer was to increase the stiffness of the open-roof Type 964, giving it the same dynamic performance as the coupe while minimizing additional weight. The careful balancing of performance against weight is extremely familiar to us and we’re delighted to have been able to support Singer and their clients with this solution.”

Mazen Fawaz, chief strategy officer at Singer, said, “Our clients are some of the most discerning drivers in the world. To achieve the standards they have come to expect, we work only with the best, and our search for expertise in this area led us to Red Bull Advanced Technologies. Since 2009 our approach has brought heritage together with cutting-edge engineering, and Red Bull’s mastery of advanced materials, simulation and structural analysis perfectly exemplifies this approach. The results underline the extraordinary lengths we go to in our relentless pursuit of excellence.”

Related news, Unnamed Mercedes‑Benz Mythos model undergoes arctic testing