The dynamic between grip and drag dictates design preparation for each race over the Formula One calendar.

“Good grip enables the car to go faster but downforce also produces drag, which must be overcome by engine power,” says Peter Machin, head of aerodynamics at Renault Sport Formula One Team. “The ultimate goal is to generate a vertical force and push the tires into the ground while minimizing drag.”

The workflow of a Formula One car design is a 365-day-a-year process. Throughout the season, surfaces are continually being adjusted to accommodate the track, the driver and climate conditions.

“Our car could be seen as an aerospace prototype,” says Luca Mazzocco, head of technological partnerships, Renault Sport Formula One Team. “We need to deploy innovation race-by-race if we want to be a credible challenger, and that can be on a weekly basis and on 21 different tracks around the globe.”

Seventy percent of a car’s performance stems directly from its aerodynamic behavior.

Incremental improvements are made on day-to-day basis as stiffness, weight and cost effectiveness are balanced. Not surprisingly, aerodynamics is the largest department at Renault Sport Formula One Team; it commands the biggest budget and its supercomputer produces 60TB of data each week.

Aerodynamics involves both physical testing and simulation. Aside from the inherent limitations of a wind tunnel, the nature and extent of physical testing is restricted by Formula One regulations. The use of computational fluid dynamics (CFD) software is critical and, for more than 15 years, the company has been using Simcenter STAR-CCM+ software from Siemens.

As the use of strong, lightweight carbon fiber is critical to a racing car’s aerodynamic performance, Renault Sport Formula One Team also uses the Fibersim portfolio of software for composites engineering from Siemens PLM Software. This is used to manage the design, analysis and manufacture of fiber-reinforced composite parts.

Paul Cusdin, head of CFD for Renault Sport Formula One Team, says, “Our challenge is to ensure that the computational domain correlates with data captured from the wind tunnel, so we can ensure that every design upgrade will actually match up with reality.”

The focus is not only on speed; CFD is used for thermal simulation because an overheated car is a potential danger and must be called into the pits. On the other hand, there are clear restrictions on how much cooling can be applied to the engine during a race.

CFD is also used to simulate the action on the track, particularly when another vehicle directly in front is creating turbulence that not only makes it difficult to overtake it but could lead to a critical loss of downforce in one part of the car.

Another major question for the CFD experts at Renault Sport Formula One Team is how to get the most from the tires. It is not easy to model the geometry and wake behavior of tires in a wind tunnel, especially in high-speed corners when tire shape fluctuates. Another consideration is that within a tunnel, wind moves over the car rather than the car moving over ground.

Another major question for the CFD experts at Renault Sport Formula One Team is how to get the most from the tires. It is not easy to model the geometry and wake behavior of tires in a wind tunnel, especially in high-speed corners when tire shape fluctuates. Another consideration is that within a tunnel, wind moves over the car rather than the car moving over ground.

“This area is where we have the least correlation between the physical and the computational,” says Cusdin. “Yet we need to extract more from the tires, for example, by placing geometry around the floor of the car in the best way possible for aerodynamics performance.”

CFD offers a design team insight into what happens in the wind tunnel.

“It shows the precise airflow over the car and tells us why we are getting certain results,” says Cusdin. “For example, simulation shows whether a vortex is above the wing or below it. It can introduce heat, which we cannot do in the wind tunnel, and illustrate thermal interaction. It tells us more about a specific design, indicating if it is close to optimal. In short, the computational domain not only augments the physical domain, it also improves it.”

In one instance, members of the CFD team were looking to incorporate the power of the fast-moving air from the exhaust to enhance downforce, but results on the track were disappointing.

By further analyzing the physics, they discovered that modeling the exhaust as a steady jet rather than a series of pulses had inadvertently led Renault Sport Formula One Team designers down the wrong path. CFD solved this engineering challenge by simulating the pulse aspect and allowing engineers to visualize its repercussions on the airflow.

“When we test different geometries in the wind tunnel, we learn whether they are better or worse than the prior design, but we only rarely understand exactly why,” says Cusdin. “Understanding the vortex created by the front wing is particularly important because the rest of the car depends on that; yet CFD has been rather poor at capturing the wake structure at the front of the car.

“However, Siemens PLM Software introduced a turbulence model within the latest enhancements for Simcenter STAR-CCM+ and now we can look at all the vortices shed off the front, side and rear and clearly see how these react with the field downstream.”

The CFD team aims to calculate and recalculate design changes within a few hours so that clear information is available for designers.

“Our simulation pipeline is very simple,” says Cusdin. “Other CFD software requires extensive coding, but we only write code for each new set of environmental parameters. This is the unique advantage of Simcenter STAR-CCM+ and it means that we can create templates for the design team.”

As a result, design engineers can replace any surface and continuously re-run the same simulation. By accessing templates from within the system, they do not even have to open Simcenter STAR-CCM+ or see the solver. In this way, the CFD team iterates in step with the design department as aerodynamic shapes are assessed for performance.

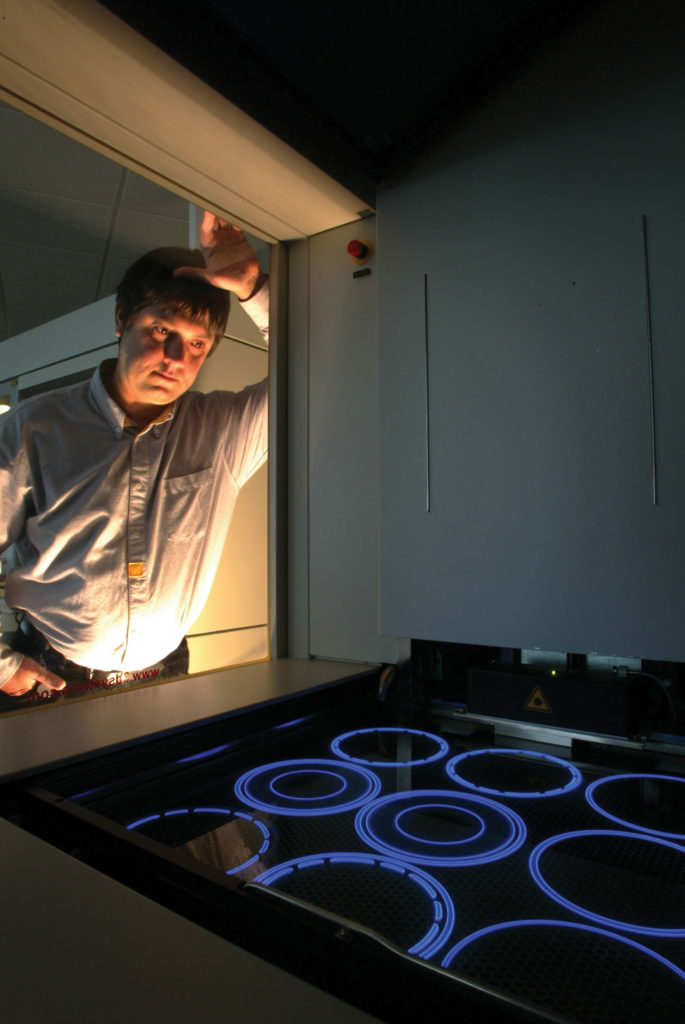

Promising geometries are sent to the wind tunnel and reassessed through CFD. Designs are released for manufacture only when results from the wind tunnel match those from simulation. In accordance with Formula One regulations, the wind tunnel car is a 60% scale model.

Because of the fast testing cycle and shape complexity, most wind tunnel model parts are made using additive manufacturing, a technology that is also involved in making several full-scale car parts. In some cases, this process can be completed overnight, though more complex parts may take several weeks.