Porsche Engineering has developed the TABASKO construction method, in which polypropylene components are reinforced with strategically placed carbon fiber tapes. This helps reduce the use of plastic materials and increase the use of post-consumer recycled material, and supports lightweighting without sacrificing rigidity. TABASKO takes its name from the German for ‘tape-based carbon-fiber lightweight construction’.

Plastic polypropylene (PP) is often used in the interior of a vehicle. But PP has its disadvantages. Michael Johann, specialist project manager for body system development, explained, “Rigidity and heat resistance do not count among the positive properties of polypropylene. Glass fiber is typically added to improve it.” This glass-fiber-reinforced plastic is called PP-GFx.

Johann is “constantly evaluating new design principles that can be used to combine maximum strength and minimum weight”, Porsche says.

This led to the creation of the TABASKO process, based on the hypothesis that PP currently used could be reinforced with a few continuous carbon fiber tapes, reducing wall thicknesses of components without losing stability.

Prototype

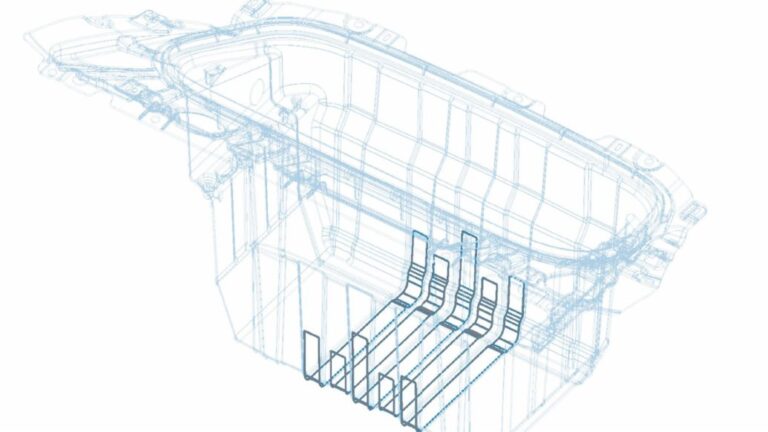

In a collaborative effort, Johann and Porsche materials expert Frank Häusler received support from Hubert Stadtfeld, project manager for lightweight construction in production development for strategic product and process design at Porsche Engineering, to test the TABASKO prototype on the luggage tray of the Porsche Taycan.

Originally made of glass-fiber-reinforced plastic, the series component was 65cm long, 120cm wide and 52cm high. For the TABASKO test, a 1.8mm-thick PP-GFx, reinforced with 0.2mm thin carbon-fiber tape, was used. The percentage of carbon by weight was 1%.

Three tests were carried out with the prototypes: a comparative punch test on both the series-production luggage tray and its counterpart made of TABASKO material; a four-point bending test; and an impact strength test.

Test results

For the punch test, a 66% higher compressive force on the TABASKO luggage tray was required to achieve the same maximum permissible deflection. At the same time, the component was 15% lighter than the series-production luggage tray.

For the four-point bending test, developers cut rectangular strips out of the bottom surface of the luggage tray. The strips were then bent from both sides, each at room temperature and 90°C. The tapes were placed in the component as upper and lower belts in alternation, forming a “virtual sandwich”. The spacing in the peripheral positions enabled high flexural rigidity with minimal use of tape. “Clearly visible was that the rigidity of the tape-reinforced samples was higher by a factor of 2.5 to 2.8,” explained Häusler.

The third impact strength test was a test appropriate for when foam injection molding is used, as it is in the manufacture of the TABASKO material. “In doing so, this results in foam structures that could cause the impact resistance of the base material to suffer,” said Johann. The test showed that, in combination with tape on the tensile side, the impact resistance was approximately five times better.

Production

“Now came the most important step: transfer to series production,” said Häusler. “The question was, how can you produce up to 80,000 parts a year— in a fully automated way and cost-neutral compared to today’s process?”

Johann, Häusler and Stadtfeld worked together with a supplier to develop a production process using conventional automated injection molding machines. “The tapes are inserted into the forming tools by means of a handling device and attached to either the top or the bottom of the component using vacuum channels,” explained Johann. “In principle, new machines or processes are not required, which is extremely advantageous for production costs.”

The preliminary development of the new material has been completed and the technical department responsible for the luggage trays has already signaled interest in series production for future vehicles. Discussions are currently ongoing with the plastic suppliers.

Six patents have been filed for TABASKO, for the material structure, the production method, the tool technology and the process sequence in series production.

In related news, a research team at Wichita State University has developed a new nanocomposite material that could significantly enhance the strength, durability, multifunctionality and performance of composite structures. Click here to read the full story