PMW goes behind the scenes at Stratasys’s center of excellence for powder additive manufacturing, which produces race car parts for TRD and NASCAR.

An hour north of Austin, Texas, is the city of Belton, home of one of North America’s largest additive manufacturing (AM) production facilities. Established in 1995 by Harvest Technologies before that company was acquired by Stratasys in 2014, the 20,000ft2 factory and its 85 staff specialize in end-use AM polymer parts for automotive and motorsport, aerospace and other industries.

An hour north of Austin, Texas, is the city of Belton, home of one of North America’s largest additive manufacturing (AM) production facilities. Established in 1995 by Harvest Technologies before that company was acquired by Stratasys in 2014, the 20,000ft2 factory and its 85 staff specialize in end-use AM polymer parts for automotive and motorsport, aerospace and other industries.

“Our focus going forward in Stratasys is around moving into polymer manufacturing applications,” says Rich Garrity, chief industrial business officer at Stratasys. “That’s where we see the biggest opportunities. We now have built out our portfolio to cover all five main additive polymer processes. We’ve been investing in SAF (selective absorption fusion), which is a high-speed sintering process that we believe has the potential to displace low-volume injection molding as a traditional source.”

“Our focus going forward in Stratasys is around moving into polymer manufacturing applications,”

Rich Garrity, chief industrial business officer at Stratasys

Belton has become the powder center of excellence for Stratasys Direct Manufacturing (SDM). The site’s printers are from both Stratasys itself and competitors like HP. Garrity says that as the company’s service bureau and manufacturing arm, SDM doesn’t restrict customer choice by limiting itself to Stratasys equipment.

Selective laser sintering

Our tour of the site, which was the first AM facility in North America to become AS9100/ISO 9001 certified, begins appropriately with SLS (selective laser sintering). SLS was invented at the nearby University of Texas at Austin and was the first AM technology deployed by Harvest in its original building.

Today, Belton has 31 SLS machines in operation from multiple suppliers, with seven more on the way from the former Solid Concepts facility in Valencia, California, as part of SDM’s consolidation of powder-based operations in Texas. The company is working with Kaizen consultants to reconfigure Belton for maximum efficiency and plans are under consideration to expand it in the future.

Today, Belton has 31 SLS machines in operation from multiple suppliers, with seven more on the way from the former Solid Concepts facility in Valencia, California, as part of SDM’s consolidation of powder-based operations in Texas. The company is working with Kaizen consultants to reconfigure Belton for maximum efficiency and plans are under consideration to expand it in the future.

A highlight of the SLS area are the large-frame machines of EOS, with which Stratasys works in partnership. There will ultimately be eight such machines operational in Belton, which the company states will be the largest installed base of large-frame EOS P7 equipment in North America. The latest P770s can build larger parts thanks to the dual-laser system and a frame area of 30in x 15in x 22in (76cm x 38cm x 56cm).

“We worked closely with the development of the technology to ensure that it met manufacturing standards”

Maricarmen Senosiain, product manager for SDM

Selective absorption fusion

Next door is the SAF production area. SAF is a powder bed fusion (PBF) process developed in Europe in the past decade, with printer sales starting in 2021.

“We worked closely with the development of the technology to ensure that it met manufacturing standards,” explains Maricarmen Senosiain, product manager for SDM. “The consumables are less [compared with competing PBF methods] and energy consumption is reduced, so it’s more cost-accessible for production components. It also gives you more in-depth reporting analytics and versatility in how you’re able to print.”

At the time of our visit, Belton had six operational H350 SAF printers with plans for four more to come on stream by the end of 2023 as production ramps up. The longer-term plan is for a total of 12. SDM used the SAF printers at Belton to build the interior door handle surrounds for Toyota Racing Development’s (TRD) new GR86 Cup race cars as part of a wider technical partnership with TRD.

From mixing to post-processing

The tour moves on via the mixing room, where 300kg batches of white powder material of more than a dozen different types are prepared for the printers in a 90-minute process. Full materials traceability – especially important for spec-based production components in the aerospace industry – is provided.

The nearby breakout room is where the freshly baked ‘part cakes’ are broken apart to reveal the newly additive-manufactured parts within. The process here is a mixture of manual intervention and automation, with compressed air and small media introduced to help clean the part up. Jeff Washburn, director of manufacturing at Belton, notes that more automation is possible with SAF components.

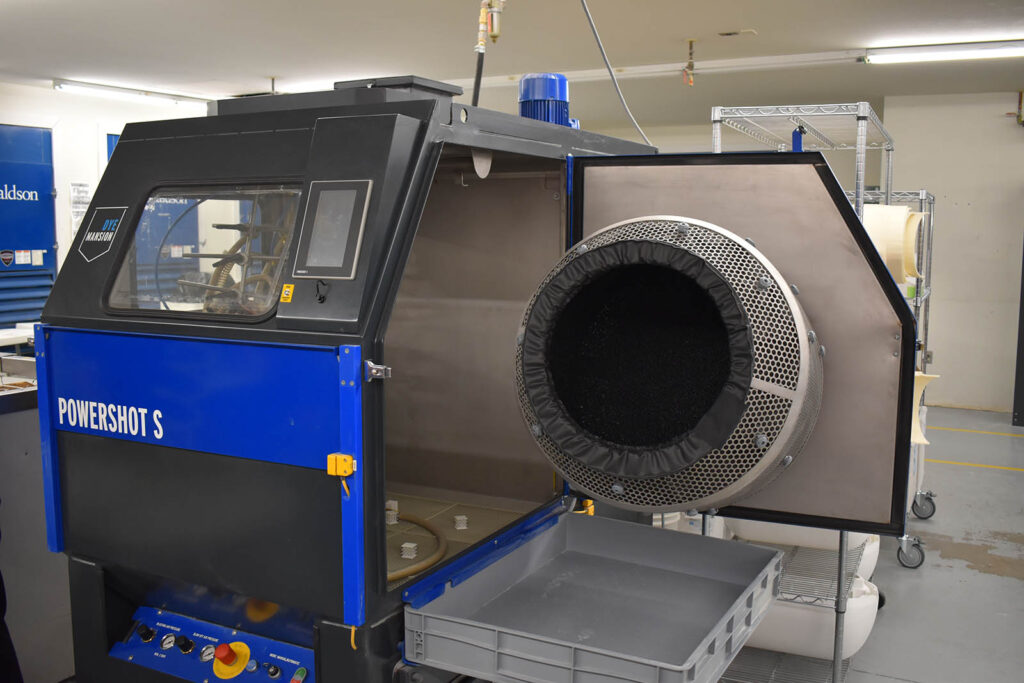

We’re shown a Dye Mansion Powershot C that tumbles parts to clean them in less than 10 minutes, when a purely manual approach might take 15. A Powershot S performs a vapor smoothing/polishing process on parts including NASCAR windshield ducts – one of several stock-car components made by SDM, with more than 800 ducts produced so far.

Further post-processing steps may be in order, depending on whether it’s an end-use or prototype part (the facility’s output is split around 60/40 in favor of production work). The team handles everything from fast-turnaround, ‘strip and ship’, to a detailed, top-coated master finish, potentially also requiring assembly or fitment of rivets, inserts and the like. As Washburn acknowledges, Belton’s activities are a contrasting blend of high-tech, automated production and old-school manual processing and inspection.

Further post-processing steps may be in order, depending on whether it’s an end-use or prototype part (the facility’s output is split around 60/40 in favor of production work). The team handles everything from fast-turnaround, ‘strip and ship’, to a detailed, top-coated master finish, potentially also requiring assembly or fitment of rivets, inserts and the like. As Washburn acknowledges, Belton’s activities are a contrasting blend of high-tech, automated production and old-school manual processing and inspection.

Awaiting their turn on the shelf for post-processing is a batch of front-end camera mounts for the Roush F-150. Like the NASCAR ducts, they are made from SAF Nylon 11.

Belton has a full-scale, car-sized paint booth for final finishing. Demand is such that it’s in operation around the clock and often at weekends, too. The same goes for the nearby metrology lab, whose mainstay is verifying high-requirement production parts for aerospace customers.

FDM and MJF

There are two production areas left to see. The first caters for FDM (fused deposition modeling) and comprises a bank of 10 Stratasys F900 printers that printed the hood vents for TRD’s GR86 Cup cars. This area, too, will also be expanded after the closure of Valencia, with four more machines on the way.

The F900s provide Belton’s only non-powder-based AM capability and were located here because of the site’s familiarity with, and certification for, high-requirements work for aerospace customers.

Our final stop is a room of HP Multi Jet Fusion (MJF) printers. Washburn describes the process as, “clean, quick and efficient”, but the machines have a larger footprint than SAF. This department, with 10 units, can produce 18-25,000 parts of month at peak times – a major contribution to the Belton facility, which processed more than 400,000 parts in 2022.