Rimac Technology has engineered, designed and integrated the battery system, e-axles and electronic control units for the Bugatti Tourbillon hyper sports cars. Working in collaboration with Bugatti Rimac’s engineering teams, Rimac has designed an 800V hybrid system that integrates with the Tourbillon’s naturally aspirated 8.3-liter V16 engine.

“The Bugatti Tourbillon project represents a perfect showcase of Rimac Technology’s capabilities as a full-system integrator and technology provider. We’ve leveraged our decade of experience in developing high-performance electric powertrains to create a hybrid system that not only delivers extraordinary performance but also demonstrates remarkable efficiency and packaging innovation,” said Mate Rimac, founder and president of the Rimac Group and CEO of Bugatti Rimac and Rimac Technology.

“The fact that the Tourbillon, despite its complex hybrid architecture, weighs less than its predecessor is a testament to our commitment to pushing the envelope of possibility in every project.”

Electric powertrain

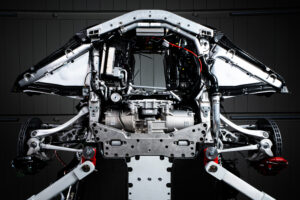

At the heart of the Tourbillon is Rimac Technology’s electric powertrain, featuring three high-performance electric motors – two mounted at the front axle and one at the rear. These motors collectively produce 800hp and can spin up to 24,000rpm, powering an e-axle that boasts one of the highest power densities in the industry.

The electric powertrain also features Rimac’s silicon carbide inverter technology with accompanying proprietary software ensuring not only high performance but also exceptional efficiency and operational safety. Despite its three motors, battery pack and V16 engine, the Tourbillon is both shorter and lighter than its predecessor, which was solely powered by a quad-turbo W16 engine.

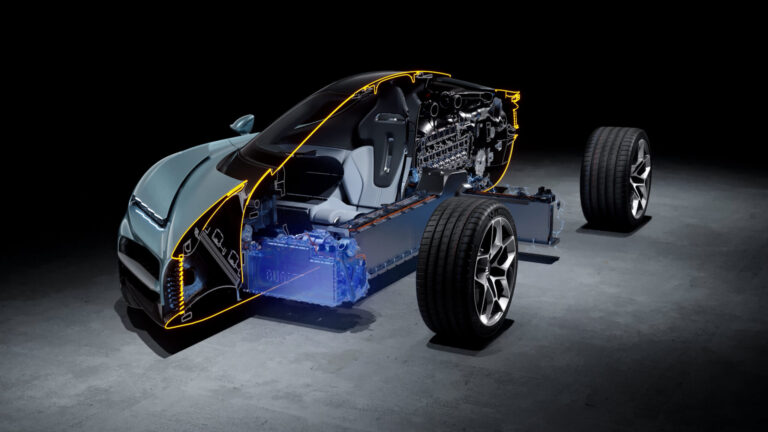

The hybrid system is powered by Rimac Technology’s 25kWh battery pack, featuring an innovative T-shaped design that serves as both an energy storage system and a structural component of the vehicle. This 800V battery system incorporates oil-cooling technology and over 1,500 individual cells immersed in oil, managed by the company’s fifth-generation battery management system (BMS). The BMS, developed in accordance with ASPICE Level 2 standards and supporting the highest automotive safety standard (ASIL D), has been designed to ensure optimal performance, longevity and safety throughout the battery’s lifecycle.

The complete rear powertrain assembly – including the V16 engine, 8-speed dual-clutch transmission, torque-vectoring differential and the 250KW rear electric motor – weighs around 430kg, matching the weight of the Chiron’s engine. The front electric axle, housing two independent motors and dual inverters, adds minimal weight while providing instantaneous torque and enabling sophisticated and precise torque control capabilities.

The electric motors serve multiple functions beyond propulsion, acting as starter motors, generators and performance enhancers. This multifunctional approach eliminates the need for traditional 12V starting systems and belt-driven accessories. The system enables over 60km of pure electric driving range, while also providing seamless torque fill to complement the naturally aspirated V16’s power delivery characteristics.

“This is exactly what we’ve always been exceptional at, extremely bespoke, high-performance, low-volume applications that are engineered without compromise. Projects like this will always serve as a showcase of our ultimate capabilities and what’s possible when there are no constraints. But as well as these showcase projects, we also produce hundreds of thousands of battery and powertrain units annually, working with the likes of Porsche, BMW, CEER Motors and many others. It’s our aim to provide the same engineering excellence and innovation we bring to projects like the Tourbillon to hundreds of thousands of other vehicles each year, helping established OEMs to bridge the gap to electrified vehicles,” added Nurdin Pitarević, COO, Rimac Technology.